- Contact Person : Mr. Huang Johnny

- Company Name : Jinan Railway Vehicles Equipment Co., Ltd.

- Tel : 86-531-88305599,88305699,88305809

- Fax : 86-531-88305656

- Address : Shandong,Jinan,73,Huaicun Street, Huaiyin District,Jinan,Shandong,China

- Country/Region : China

- Zip : 250022

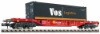

G17BK oil tank wagon

G17BK railway intemal heating tank car is mainly used to transport crude oil, heavy diesel fuel, lubricating oil and common viscous oil media by up loading and down unloading. It is a four-shaft axle railway tank wagon without centre sill.

This wagon has no centre sill. At one end of the tank are vestibule and manpower brake system. Within the heatine system, a sinuous coil equipmefit in the tank is set to heat the media inside tank by steam.

The body of the tank is vertical cylinder weld structure, formed by welded standard ellipsoidal end and top and bottom groups of tank shells.The body of the tank is made of low alloy high streneth structural steel. On the top of the tank, a switchin 567mmLinGde diaketer manhole (also as a charging hole) is set. The bolt of the manhole is one-piece greaseimmersed. The manhole socket is equipped with a cubage scale, the height above which is the liquor level of the effective volume.

The sill-pulling apparatus consists of welded tractire sill, bolster,end sill , side sill and so on. The web of the bolster is connected with the tank body into a whole. Integral casting steel is used in the rear graft lug and centre plate. The body centre plate is forged.

Heating device : The heating device employs the sinuous coil structure set within the tank, that is, 12 limes of heating pipes are vertically set around the body from the bottom. Heating pipes are fully welded structure. They are divided into two groups, the entries of which are connected with the admission main pipe on the bottom by the pipes. The heating stream can supply heat and at the same time heat two groups of pipes through the main pipe. Besides, a pipe branches out from the main external admission pipe and connects with a formed heating jacket for oil drainage pipes . An intemal thread ball valve is set on the branch pipe to control the flow amount of steam coming into the oil drainage pipe heating jacket. The exits of two groups of heating pipes are set in the bottom of the tank, which discharge condensation water directly.

Loading device: a common diameter of 100mm ball valve is set at the bottom of the tank body. The discharge pipe is equipped with a heating jacket. When the oil is unloaded, both sides of the discharge are used to drain the oil to the ground facilities: when loaded, it is carried out through the manhole.

The coupler and butter is of 13A up operation coupler and ST buffer.

Brake device: It is equipped with air brake and hand brake. Its brake pipe pressure meets the requirement of 5OOkPa and 600kPa. It includes:ST2-250 bidirectional brake shoe slack adjuster, weaving brake hose assembly, high frication composite brake shoe, 254mm-diameter integralspinning sealed type brake cylinder, Austempered Ductile Iron liner bushing, modified 120 type control valve, stainless steel brakimg fittings and pipe system. Manual braking is NSW power hand brake. The empty vehicle automatic regulator is of KZW-4GA type or TWG-1A type.

The bogie is K2 type and brake beam is combined type.

Loading Capacity (t) | 63 |

Tare Weight (t) | 20.8 |

Working Volume(m3) | 66.4 |

Tank Working Pressure | 0.15 |

Speed(km/h) | 120 |

Min. Radius(m) | 145 |

G17BK oil tank wagon